Asset Management

Empowering Smarter, Safer, and Longer-Lasting Infrastructure

The lifespan of facility assets extends far beyond initial construction. Each structure evolves under the pressures of aging infrastructure, regulatory change, and continuous operational demands. Orbital’s Asset Management services provide a holistic approach to preserving asset integrity and optimizing performance across the lifecycle.

Since 1969, we have partnered with clients to identify, assess, and resolve issues within existing facilities. Our programs combine engineering expertise, risk-based analytics, and advanced data technology to deliver proactive solutions – empowering your operations team to focus on production while Orbital monitors and mitigates hidden risks before they become costly problems.

Condition Risk-Based Inspection (RBI) Programs

Prioritizing repairs through data-driven intelligence.

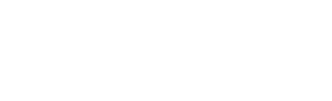

Orbital pioneered the implementation of risk-based inspection methodologies to evaluate and rank plant structures by condition, consequence, and probability of failure. Our proprietary RBI model integrates safety, environmental, and operational factors to systematically identify and prioritize maintenance activities based on measurable risk factors.

By leveraging this approach, clients transition from reactive maintenance to a predictive and proactive model – reducing downtime, optimizing capital allocation, and extending asset life. Orbital manages large-scale RBI programs across multiple facilities, delivering consistent and traceable workflows through our digital asset management tools. Maintenance activities are fully documented and accessible, supporting long-term asset reliability and performance.

Turnkey Engineering and Repair Management

From identifying deficiencies to delivering solutions.

Orbital’s capabilities go beyond inspection – we engineer and deliver lasting repair solutions. Our experienced structural and mechanical engineers design both standard and complex repair solutions tailored to the specific condition, risk, and operational requirements of each asset. We contract with trusted partners to execute repairs and provide direct field oversight, including Quality Assurance and Quality Control (QA/QC) verification, to confirm repairs meet defined technical requirements.

We specialize in asset management programs that integrate condition assessments and risk prioritization into repair planning and project execution – focusing maintenance investments on the areas that extend asset life, improve reliability, and reduce the likelihood of costly disruptions.

Tools and Technology

Innovative field technology and advanced integrations turn field data into actionable insight.

Orbital continuously invests in industry leading field data collection and processing technologies. Our ORBITS® Risk-Based Inspection Tracking System serves as a centralized digital repository for inspection data, risk modeling, and reporting dashboards.

Through advanced integrations with tablet-based applications, Geographic Information Systems (GIS), Unmanned Aerial Systems (UAS), LiDAR, 3D mapping , photogrammetry, infrared thermal imaging, and AI-driven analytics, Orbital delivers timely, actionable insight to asset owners – reducing data processing cycles, improving field situational awareness, and supporting smarter, more proactive maintenance strategies.

Compliance and Safety Audits

Navigating OSHA, MSHA, and regulatory standards with confidence.

Orbital’s compliance specialists conduct comprehensive OSHA and MSHA walking-working surface, fixed ladder, and fall protection audits to identify hazards and develop code-compliant corrective solutions. Our evaluations align with current regulatory requirements, including OSHA 29 CFR 1910 and 1926, applicable MSHA 30 CFR Parts 56, 57, and 77, and ANSI/ASSP Z359 Fall Protection Code.

Supported by experienced engineers, Orbital delivers compliant fall protection system designs, calculations, and documentation to help facilities remain safe, audit-ready, and fully aligned with operational and regulatory expectations.

Certifications and Expertise

A multidisciplinary team certified to leading industry standards.

Our inspection and engineering professionals maintain certifications across the industry’s most critical disciplines. This depth of expertise underpins verified accuracy, technical excellence, and trusted compliance oversight throughout every Orbital project.

Projects

Asset management powered by engineering insight and experience throughout the asset lifecycle.