Heavy Industrial Projects

See how Orbital supports heavy industrial facilities in developing projects, executing work, and managing essential industrial assets.

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Scope of Work:

- Performed an out-of-service API 653 tank inspection, including a Magnetic Flux Leakage (MFL) floor scan

- Evaluated tank floor condition and investigated MFL indications using ultrasonic thickness testing (UTT)

- Documented and marked areas approaching T-minimum for repair

- Developed API 653–compliant engineering designs for complete tank floor replacement

- Designed modifications to accommodate relocation of multiple tank shell nozzles

- Defined non-destructive examination (NDE) requirements associated with repairs

- Provided on-site quality assurance and quality control oversight throughout all phases of construction and repair

- Verified completion and documentation of all corrective actions

- Prepared and issued final inspection documentation confirming fitness for service

Deliverables:

- API 653 out-of-service inspection report

- MFL floor scan results and UTT verification data

- Detailed API 653–compliant repair drawings for full floor replacement

- NDE procedures and inspection requirements

- Quality assurance and quality control oversight documentation and repair verification records

- Final inspection report confirming safe, compliant return to service

Project Highlights:

- Orbital executed a comprehensive API 653 inspection and major repair program for a 99,500-gallon storage tank, identifying floor corrosion risks through advanced MFL scanning and targeted ultrasonic testing. Early detection of low-thickness areas approaching T-minimum allowed Orbital to design proactive repairs before loss of containment could occur. The project required complete tank floor replacement and the relocation of multiple shell nozzles – complex modifications successfully delivered through Orbital’s integrated inspection, engineering, and quality assurance and quality control oversight. The repairs restored the tank to a safe, compliant operating condition, extended its remaining service life, and reduced the client’s risk of unplanned outages and future repair costs.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

Orbital’s Role in Critical Structures Management Programs

Oil and Gas

Orbital’s Role in Critical Structures Management Programs

Oil and Gas

Scope of Work:

- Implemented and managed plantwide Critical Structures Management Programs for multiple clients

- Performed risk ranking and structural analysis across large, complex asset inventories

- Planned and executed inspection programs based on asset criticality and risk level

- Conducted routine and advanced inspections of process vessels, exchangers, buildings, foundations, stacks, and pipe racks

- Managed inspection data, prioritization, and repair recommendations within Orbital’s database

- Developed engineered repair solutions for assets requiring non-standard or complex repairs

- Supported execution and delivery of repairs to prevent recurrence of structural issues

Deliverables:

- Risk-ranked asset inventories and inspection schedules

- Inspection reports with prioritized findings and repair recommendations

- Database-driven tracking of inspection results and mitigation actions

- Engineered repair designs and analysis for complex structural conditions

- Ongoing program management documentation and reporting

Project Highlights:

- Orbital has provided long-term Critical Structures Management Program support for one of the world’s largest refineries, overseeing inspection and risk management activities for an asset inventory exceeding 15,000 structures. By assigning risk levels to each asset and aligning inspection frequency and level accordingly, Orbital established a systematic, defensible approach to managing structural integrity at scale. Inspection findings are captured, ranked, and tracked within Orbital’s database, allowing issues to be prioritized and addressed before they escalate. When standard repair solutions are not sufficient, Orbital’s engineering team delivers customized analyses and engineered repairs, helping clients proactively manage risk, reduce repeat issues, and maintain safe, reliable plant operations.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Featured

345k Double Breaker Interconnect Substation

Construction Management

Featured

Federal Funded Maintenance Program Management

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

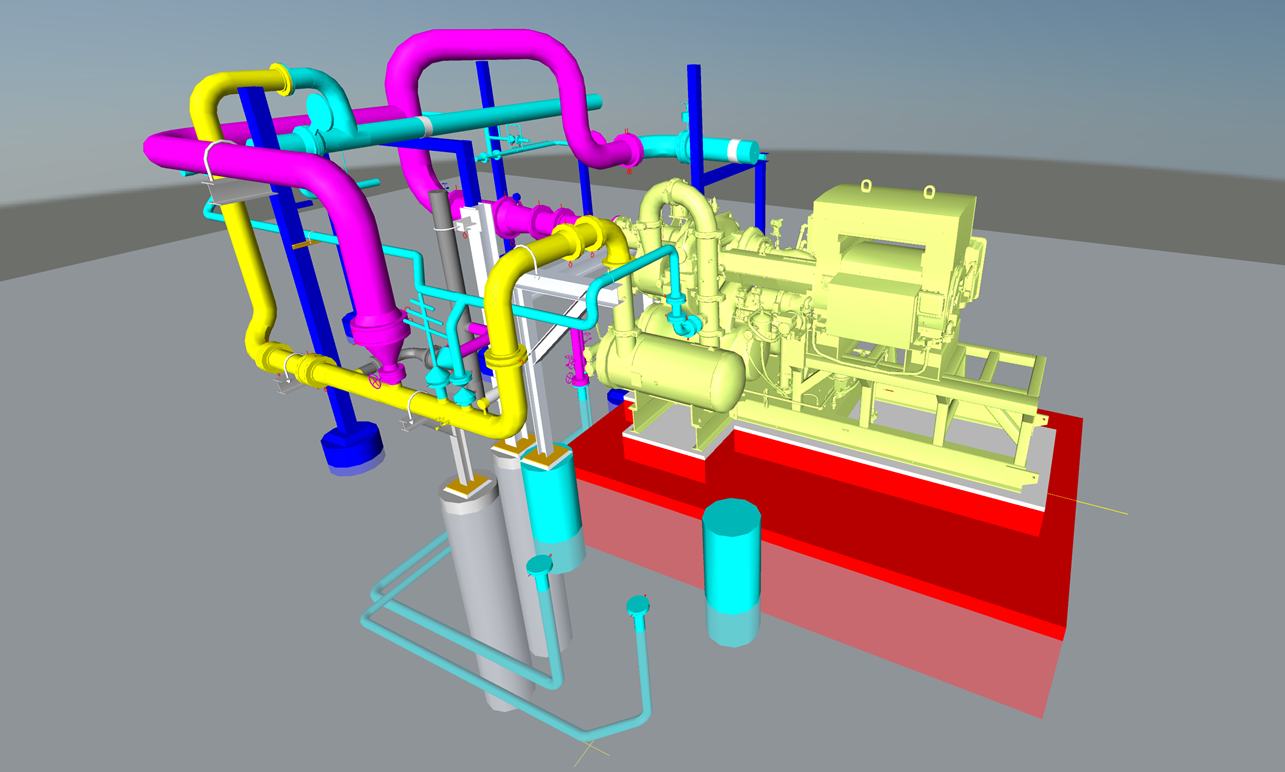

Feed Impurity Removal

Specialty Chemical

Scope of Work

- The objective of this project was to remove the oil and grease from the incoming feed flow that is utilized throughout the plant’s operations

- With these impurities being removed prior to the feed entering the Strippers, it improved the efficiency of the production at the site

- Project included installation of two oil storage tanks and six pumps with containment with all interconnecting piping, steel and supports

- A raised MCC structure on piles and a concrete pad supported transformer was added to the east of the main project area to supply power for the project and a new Delta V Cabinet with HMI was located in the new MCC building

- The existing truck parking was relocated to the northeast along with connecting existing roadways to allow for a different exit path

- New surveillance cameras were integrated with an existing camera network located at gate to the East of the proposed parking location

- Full electrical scope included adding a 13.8kV feeder, 13.8kV/480V transformer, substation building, 480V motor control center, VFD’s, UPS, panels, control stations, lighting, grounding, and associated cable tray/conduit and cables

Deliverables

- Revised site plan

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Piping, foundation and steel drawings for supporting new tanks, pumps, MCC, transformer and piping

- Grading plans, sections and details for new roadway and parking lot

- Material requisition packages for major electrical equipment – 13.8kV switch, 13.8kV to 480V transformer, substation building, 480V MCC, UPS System

- Single line diagrams, power plans, duct bank and cable tray plans, lighting plans, grounding plans, cable & conduit schedules, area classification drawings

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets, control narratives

- Scope of work documents for construction

Project Highlights

- Maintenance work was minimized significantly as a result of the project, decreasing downtime while increasing productivity.

- Total Installed Cost (TIC) – $120MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Heavy Industrial

N2 Feed Gas Compressor Replacement

Oil and Gas

N2 Feed Gas Compressor Replacement

Oil and Gas

Scope of Work

- Replaced existing feed gas compressor with a new compressor in same location

- Scope included process, piping, structural, electrical and instrumentation design activities

- Design considered pipe spooling to the maximum extent and shutdown planning for MCC modifications

- Orbital led constructability reviews to identify lifting locations and equipment staging areas for the quick turnaround window

Deliverables

- Revised P&IDs and general arrangements

- Piping plans, sections & elevations, isometrics

- Structural pipe supports drawings, compressor skid anchorage and grouting details

- Single line diagrams, cable & conduit schedules and grounding plan

- Schematic wiring diagrams, instrument list and instrument installation details

- Scope of work documents for construction

Project Highlights

- Successfully completed compressor replacement with minimal downtime. The existing compressor was demolished, and new compressor was installed and commissioned in same location in just 4 days.

- Total Installed Cost (TIC) – $2MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Substation Relocation

Specialty Chemical

Substation Relocation

Specialty Chemical

Scope of Work

- Existing client 34.5kV main substation was approaching the end of its useful life

- Orbital performed electrical and structural engineering to relocate the substation out of a central process area to eliminate overhead high voltage cable in the congested space

- Orbital subcontracted geotechnical and architectural services with trusted partners for a comprehensive offering

Deliverables

- SKM Model

- Revised site plan

- Single line diagrams, substation layouts, cable tray and conduit routing plans

- Foundation drawings, support details and cable tray bridge drawings

- Scope of work documents for construction

Project Highlights

- Project required interfacing with the utility to review impacts to the existing 34.5kV pole-mounted metering equipment and their upstream overhead distribution system. Orbital performed calculation comparison between the existing and new equipment to determine what incentives applied to the project for the client to pursue. Orbital led constructability planning sessions with client, Orbital and contractor to efficiently sequence the demolition and installation scopes.

- Total Installed Cost (TIC) – $10MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Fuel Certainty

Power Generation

Fuel Certainty

Power Generation

Scope of Work

- A severe weather event (hurricane) led to local utility assessing plant readiness to operate continuously in the event of interruption due to primary fuel curtailment

- The project goal was to improve the reliability and capacity of plant secondary fuel operations.

- At two separate dual fuel facilities, Orbital:

- Evaluated current capabilities and limitations

- Performed investigations to reduce unknowns and minimize risks

- Identified and evaluated various options to increase capabilities

- Developed cost estimate to assist in option evaluation and project funding request

- Participated in option selection and finalization of detailed project scope

- Performed detailed design for implementing the selection options at one of the facilities

Deliverables

- Process evaluation report, equipment list and material requisition packages for equipment

- General arrangement drawings, piping plans and isometrics

- Foundation plans and structural steel drawings

- Single line diagrams, power plans, lighting plans, grounding plans, cable & conduit schedules

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Total installed cost estimates at each FEL stage to support client stakeholder gate reviews

- Scope of work documents for construction

Project Highlights

- Facilities have since experienced more severe weather events without impacting generation capabilities.

- Total Installed Cost (TIC) – $10MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

SRU Revamp

Oil and Gas

SRU Revamp

Oil and Gas

Scope of Work

- Developed FEED package with +/- 10% total installed cost estimate for a sulfur recovery unit revamp

- Project aimed to address constrained capacity, frequent faults and compliance gaps

- Orbital executed detailed design, start up and commissioning support for the project

Deliverables

- Process design basis, PFDs and P&IDs

- Material requisition packages for the new heater, boiler and tail gas treatment unit

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Foundation and steel drawings for supporting the new equipment, piping and conduit

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for demolition and installation

Project Highlights

- 80% of the linear feet of installed piping was jacketed. Laser scanning accuracy and plant 3D modeling was critical to preventing field installation issues of the jacketed piping in the field.

- Total Installed Cost (TIC) – $12MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Coal Delivery System Modification

Power Generation

Coal Delivery System Modification

Power Generation

Scope of Work

- Coal fired power generation facility client faced a dilemma with their existing barge unloader only capable of unloading barges up to a specific width, limiting the type of barge that can be used in delivery

- Further complicating the delivery, the barges that fit within the constraints of the unloader are becoming less available due to age

- Orbital developed conceptual solution for a new barge unloading system that allowed for unloading jumbo barges to the existing surge bin via deck mounted Sennebogen cranes, hoppers and conveyors on a new deck barges and incline conveyors to the existing surge bin

- Once approved, Orbital executed detailed design including procurement support in equipment specification and selection, owner’s engineering and construction support

Deliverables

- General arrangement drawings and total installed cost estimates for various solutions

- Material requisition packages for conveyors and hoppers

- Conveyor support steel drawings and foundations

- Single line diagrams, power plans, lighting plans, grounding plans, cable & conduit schedules

- Scope of work documents for construction

Project Highlights

- Project was originally deemed an “unsolvable problem” due to complexities in the design interfaces, contractual interfaces between delivery and client and limited remaining operating window for the facility. Orbital’s efficient solution allowed for the project to be authorized, and the facility is currently conducting coal unloading operations via the new unloading system. The facility operating permit has been extended since project completion making the solution benefits realized well into the future.

- Total Installed Cost (TIC) – $4MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Truck Scale Addition

Petrochemical

Truck Scale Addition

Petrochemical

Scope of Work

- The primary goal of this project was to install a new truck scale and automation to improve operating costs reducing filling times and operator interfaces and provide an opportunity to load a separate product

- Orbital performed detailed engineering required to support construction of the new scale and automated system, procurement activities for securing components needed for the project, and field construction management activities

Deliverables

- Revised P&IDs and general arrangements

- Structural pipe supports drawings, access platform and hose manifold supports

- Scale pit design and drainage drawings, sidewalk and paving modification drawings

- Schematic wiring diagrams, and cable and conduit schedules

- Scope of work documents for construction

Project Highlights

- Project significantly reduced operator exposure and human factors through successful process automation.

- Total Installed Cost (TIC) – $8 MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation