Asset Management Projects

See how Orbital supports heavy industrial facilities in developing projects, executing work, and managing essential industrial assets.

Asset Management

Mechanical Integrity (MI) Program Audit and Development

Specialty Chemical

Mechanical Integrity (MI) Program Audit and Development

Specialty Chemical

Scope of Work:

- Performed a Mechanical Integrity (MI) audit following Department of Environmental Quality (DEQ) findings at a chemical manufacturing facility

- Conducted site walks and reviewed process documentation, including P&IDs, to identify assets requiring inclusion in an MI program

- Developed an MI asset registry, established inspection boundaries, highlighted P&IDs, and defined inspection intervals

- Built a fully compliant MI program aligned with OSHA Process Safety Management (PSM) requirements and 40 CFR 68.73

- Authored and approved extensive MI program documentation and procedures

- Developed asset-specific Inspection Test Plans (ITPs) addressing anticipated damage mechanisms and inspection requirements

- Executed baseline MI inspections using API-certified and NDT-certified inspectors

- Collected field data, photographs, inspection isometrics, and prepared detailed inspection reports

- Integrated all program documentation, inspection results, and reports into Orbital’s inspection database

- Provided ongoing MI program support, including inspections, NDT, corrosion expertise, and audit services

Deliverables:

- Mechanical Integrity audit findings and asset inventory

- MI asset registry with defined inspection boundaries and intervals

- Fully developed MI program compliant with OSHA PSM and DEQ requirements

- Over 35 approved MI program documents, including policies, procedures, checklists, and training materials

- Asset-specific Inspection Test Plans (ITPs)

- Baseline internal and external inspection reports with photographs and isometric drawings

- AutoCAD-developed inspection drawings and database-integrated records

- Ongoing inspection, NDT, and audit documentation

Project Highlights:

- Orbital developed and implemented a fully compliant Mechanical Integrity program for a chemical manufacturing facility following regulatory audit findings, providing a clear path to meeting OSHA PSM and DEQ requirements. Through a comprehensive audit and asset registry process, Orbital established a strong foundation that accounted for all applicable fixed equipment and defined clear inspection boundaries and intervals. By building the MI program from the ground up – including more than 35 tailored program documents and asset-specific Inspection Test Plans – Orbital delivered a robust, facility-specific solution aligned with regulatory standards. Baseline inspections performed by certified inspectors, combined with full database integration, positioned the client for streamlined compliance, efficient work management, and long-term program sustainability.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Featured

345k Double Breaker Interconnect Substation

Construction Management

Featured

Federal Funded Maintenance Program Management

Natural Gas

Asset Management

Turnkey Fireproofing and Structural Repairs of Mechanical Equipment

Specialty Chemical

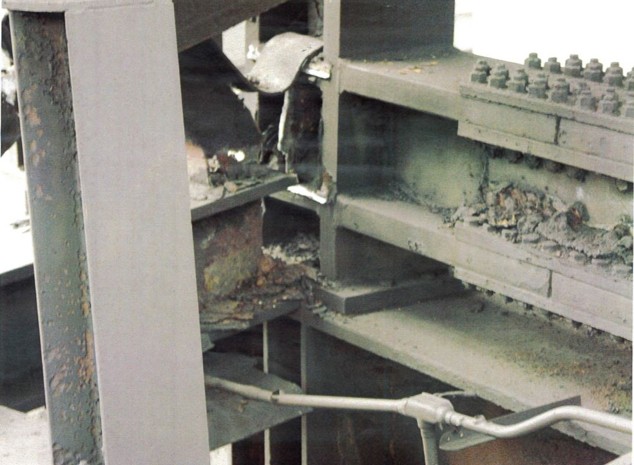

Turnkey Fireproofing and Structural Repairs of Mechanical Equipment

Specialty Chemical

Scope of Work:

- Executed a turnkey repair project for seven process vessels, providing services from inspection through repair and reinstatement

- Removed deteriorated intumescent and cementitious fireproofing from vessel column skirts and anchor bolt assemblies

- Performed abrasive blast cleaning to prepare vessel skirts for inspection and recoating

- Conducted detailed inspections, including visual assessments and ultrasonic thickness (UT) testing

- Evaluated corrosion damage using calipers and pit gauges

- Performed engineering evaluations to determine fitness for continued service

- Designed and implemented structural repairs to restore vessel integrity

- Completed final coating and reapplication of fireproofing

Deliverables:

- Inspection reports documenting visual findings and UT measurements

- Engineering evaluation and structural analysis

- Issued-For-Construction (IFC) drawings for anchor bolt replacement and base ring stiffener installation

- Completed structural repairs, including anchor bolt and stiffener installation

- Restored fireproofing and protective coating systems

Project Highlights:

- Orbital delivered a fully integrated turnkey repair solution for seven process vessels, seamlessly coordinating inspection, engineering, and field execution to minimize downtime and client oversight. Early identification of critical anchor bolt corrosion allowed Orbital to implement targeted structural repairs before further degradation could impact safety or operations. The project restored structural capacity and fire protection systems, extending the service life for each asset and improving long-term reliability. This effort highlights Orbital’s ability to deliver efficient, cost-effective repair solutions for critical infrastructure through a single, accountable team.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management Program for a Steel Mill Client

Steel

Scope of Work:

- Supported a major steel client in the development and ongoing evolution of their corporate asset management program

- Provided technical assistance in creating the original corporate inspection procedure and supporting subsequent revisions

- Applied decades of hands-on inspection experience across structural and mechanical assets at domestic and international facilities

- Defined and refined inspection and reporting processes used across the client’s enterprise

- Coordinated and supported field inspection operations to align with corporate standards and safety requirements

- Integrated emerging technologies and digital tools to enhance inspection efficiency and data management

Deliverables:

- Corporate inspection procedures and revisions

- Digital inspection data outputs supporting asset tracking and long-term program management

- Standardized inspection and reporting frameworks, including:

- Defined inspection levels

- Standard reporting formats

- Means and methods documents for individual assets

- Documentation protocols

- Boundary documents

Project Highlights:

- Orbital played a foundational role in building and evolving the client’s corporate asset management program, applying decades of inspection experience to create practical, safety-focused procedures adopted company-wide. Standardized inspection levels, reporting formats, and documentation protocols improved consistency and reliability across domestic and international operations. Through ongoing inspection programs and the integration of advanced technologies such as UAS inspections and digital data management, Orbital continues to drive continuous improvement. This long-term collaboration has helped modernize inspection practices while supporting OSHA/ANSI compliance and the client’s reliability-centered maintenance objectives.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Bridge Inspection and Turnkey Repairs

Power Generation

Scope of Work:

- Performed a comprehensive inspection of a ~1,000-foot suspension bridge spanning a major waterway

- Utilized ground-based, elevated walkway, and rope-access techniques to evaluate hard-to-reach areas

- Benchmarked findings against prior inspection reports to identify changes and new deficiencies

- Classified deficiencies by priority level to guide repair urgency and scope

- Performed engineering analysis and developed Standard Repair Procedures (SRPs) for identified deficiencies

- Coordinated access constraints, including railroad scheduling, live powerline limitations, and follow-up inspections

- Executed turnkey repair construction for the north half of the bridge, including demolition and repairs

- Provided construction coordination, safety planning, and on-site quality oversight

Deliverables:

- Phased inspection reports as segments of the bridge were completed

- A repair prioritization ranking assigned to each finding

- Standard Repair Procedures (SRPs) and engineering repair IFC drawings for Priority 1 deficiencies

- Construction coordination and quality assurance documentation

- Final inspection report and repair verification records

Project Highlights:

- Orbital delivered a comprehensive inspection and turnkey repair program for a 1,000-foot suspension bridge, combining rope-access inspection, structural engineering, and construction oversight to address complex access and safety challenges. The inspection identified 43 deficiencies, including multiple Priority 1 conditions such as widespread cracked welds, severe section loss in a primary truss chord, and extensive concrete spalling with exposed reinforcement. Orbital executed phased reporting to support timely decision-making and completed full demolition and repairs on the north half of the bridge. When lead-containing coatings were discovered mid-demolition, Orbital paused work, coordinated with regulatory agencies, and implemented a revised, compliant construction plan – allowing repairs to resume and conclude efficiently while maintaining safety, regulatory compliance, and structural integrity.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Asset Management

Emergency Response Support – Critical Failure

Steel

Emergency Response Support – Critical Failure

Steel

Scope of Work:

- Responded to an emergency inspection request following a critical failure at the Pipe Bridge end panel connection

- Performed on-site damage assessment after debris accumulation led to moisture intrusion, deterioration, and structural failure

- Deployed an emergency response team to collect field data and evaluate the condition of the truss system

- Analyzed structural distress across the Pipe Bridge, including overstressed members and failed connections

- Designed temporary shoring and permanent repair solutions

- Provided construction-phase engineering support through restoration and return to service

Deliverables:

- Emergency inspection and condition assessment findings

- Structural calculations evaluating end reactions and overstressed members

- Temporary field support and shoring designs

- Detailed repair packages for permanent restoration

- Construction support and oversight documentation

Project Highlights:

- Orbital’s rapid emergency response following a critical Pipe Bridge failure minimized risk and accelerated recovery for a facility experiencing prolonged operational disruption. The team assessed extensive structural distress within a 384-foot truss system, identifying hundreds of overstressed members and extreme end reactions approaching one million pounds. By quickly designing temporary support systems and permanent repairs, Orbital restored structural integrity and returned the Pipe Bridge to service. The successful execution of complex field repairs, including extensive welding and construction oversight, demonstrated Orbital’s ability to manage high-risk structural failures under demanding conditions.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

Asset Management Program for Power Generation Client

Power Generation

Asset Management Program for Power Generation Client

Power Generation

Scope of Work:

- Reviewed and developed corporate inspection procedures and standards for a Power Generation client

- Collaborated with client stakeholders to align documentation with industry standards and practical, field-validated inspection methodologies

- Established inspection criteria for plant structures

- Developed and introduced a new “Ready-to-Fall” risk assessment methodology to evaluate potential structural and attachment failures

- Supported post-acquisition integration by creating a phased implementation plan for newly acquired facilities to align with the corporate inspection program

Deliverables:

- Updated corporate inspection procedures and standards documentation

- “Ready-to-Fall” risk assessment framework, including:

- Visual condition rating criteria

- Risk scoring based on likelihood and severity

- Mitigation timelines to guide maintenance actions

- Phased implementation plan to support onboarding of newly acquired facilities into the corporate inspection program

Project Highlights:

- Orbital strengthened the client’s structural integrity program by pairing field-validated inspection procedures with a quantitative, risk-based methodology for managing degradation and fall hazards. The introduction of the “Ready-to-Fall” assessment model provided clear, defensible prioritization for stabilization, barricading, and repair actions across the client’s fleet. These improvements led to a measurable reduction in safety incidents related to structural failures and improved regulatory compliance across all facilities. Orbital’s approach elevated inspection practices from reactive evaluations to a proactive, data-driven strategy supporting safer, more reliable plant operations.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

Orbital’s Role in Critical Structures Management Programs

Oil and Gas

Orbital’s Role in Critical Structures Management Programs

Oil and Gas

Scope of Work:

- Implemented and managed plantwide Critical Structures Management Programs for multiple clients

- Performed risk ranking and structural analysis across large, complex asset inventories

- Planned and executed inspection programs based on asset criticality and risk level

- Conducted routine and advanced inspections of process vessels, exchangers, buildings, foundations, stacks, and pipe racks

- Managed inspection data, prioritization, and repair recommendations within Orbital’s database

- Developed engineered repair solutions for assets requiring non-standard or complex repairs

- Supported execution and delivery of repairs to prevent recurrence of structural issues

Deliverables:

- Risk-ranked asset inventories and inspection schedules

- Inspection reports with prioritized findings and repair recommendations

- Database-driven tracking of inspection results and mitigation actions

- Engineered repair designs and analysis for complex structural conditions

- Ongoing program management documentation and reporting

Project Highlights:

- Orbital has provided long-term Critical Structures Management Program support for one of the world’s largest refineries, overseeing inspection and risk management activities for an asset inventory exceeding 15,000 structures. By assigning risk levels to each asset and aligning inspection frequency and level accordingly, Orbital established a systematic, defensible approach to managing structural integrity at scale. Inspection findings are captured, ranked, and tracked within Orbital’s database, allowing issues to be prioritized and addressed before they escalate. When standard repair solutions are not sufficient, Orbital’s engineering team delivers customized analyses and engineered repairs, helping clients proactively manage risk, reduce repeat issues, and maintain safe, reliable plant operations.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Featured

345k Double Breaker Interconnect Substation

Construction Management

Featured

Federal Funded Maintenance Program Management

Natural Gas

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

OH-Crane, Crane Runway and Building Inspection

Steel

Scope of Work:

- Performed a comprehensive technical inspection of an industrial building, crane runway system, and overhead bridge crane at a major manufacturing facility

- Verified structural integrity of building framing and crane runway support systems

- Assessed condition and alignment of crane rails, runway beams, and associated structural components

- Conducted a full OSHA/ASME-compliant overhead crane inspection during a single coordinated site mobilization

- Deployed a multidisciplinary team of structural inspectors, scanning technicians, and certified overhead crane specialists

- Utilized aerial lifts, top-side runway access, and Elios 3 caged drone technology for difficult-to-access areas

- Performed alignment verification using Total Station surveying methods

- Applied visual, hands-on, and targeted non-destructive testing (NDT) techniques

- Executed mechanical, structural, electrical, and functional testing of overhead crane components

- Provided real-time notification of critical or out-of-service safety findings

Deliverables:

- Structural inspection findings for building framing and crane runway systems

- OSHA/ASME-compliant overhead crane inspection report

- Runway alignment measurements, including elevation, sweep, span, and cross-levelness data

- Severity-ranked deficiency listings with tagged photographs and measurement documentation

- Conceptual repair sketches for identified structural and runway deficiencies

- Preventive maintenance, repair, and long-term monitoring recommendations

- Integrated inspection report capturing all findings from a single mobilization

Project Highlights:

- Orbital delivered a fully integrated, multi-discipline inspection of an industrial building, crane runway, and overhead crane system in a single site mobilization, minimizing operational disruption and eliminating the need for multiple specialty contractors. By combining structural inspection, advanced scanning, precision alignment verification, and OSHA/ASME-compliant crane evaluation, Orbital provided a complete system-level assessment of both structural and mechanical performance. The inspection identified runway alignment deviations, localized structural corrosion, and typical crane component wear, allowing Orbital’s engineering team to develop prioritized repair recommendations and conceptual solutions. This project highlights Orbital’s ability to deliver efficient, technically rigorous inspection programs that support safe, reliable crane operations in complex industrial environments.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

API 653 Tank Inspection and Floor Replacement

Specialty Chemical

Scope of Work:

- Performed an out-of-service API 653 tank inspection, including a Magnetic Flux Leakage (MFL) floor scan

- Evaluated tank floor condition and investigated MFL indications using ultrasonic thickness testing (UTT)

- Documented and marked areas approaching T-minimum for repair

- Developed API 653–compliant engineering designs for complete tank floor replacement

- Designed modifications to accommodate relocation of multiple tank shell nozzles

- Defined non-destructive examination (NDE) requirements associated with repairs

- Provided on-site quality assurance and quality control oversight throughout all phases of construction and repair

- Verified completion and documentation of all corrective actions

- Prepared and issued final inspection documentation confirming fitness for service

Deliverables:

- API 653 out-of-service inspection report

- MFL floor scan results and UTT verification data

- Detailed API 653–compliant repair drawings for full floor replacement

- NDE procedures and inspection requirements

- Quality assurance and quality control oversight documentation and repair verification records

- Final inspection report confirming safe, compliant return to service

Project Highlights:

- Orbital executed a comprehensive API 653 inspection and major repair program for a 99,500-gallon storage tank, identifying floor corrosion risks through advanced MFL scanning and targeted ultrasonic testing. Early detection of low-thickness areas approaching T-minimum allowed Orbital to design proactive repairs before loss of containment could occur. The project required complete tank floor replacement and the relocation of multiple shell nozzles – complex modifications successfully delivered through Orbital’s integrated inspection, engineering, and quality assurance and quality control oversight. The repairs restored the tank to a safe, compliant operating condition, extended its remaining service life, and reduced the client’s risk of unplanned outages and future repair costs.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation