Heavy Industrial Projects

See how Orbital supports heavy industrial facilities in developing projects, executing work, and managing essential industrial assets.

Heavy Industrial

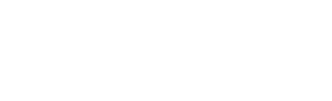

N2 Feed Gas Compressor Replacement

Oil and Gas

N2 Feed Gas Compressor Replacement

Oil and Gas

Scope of Work

- Replaced existing feed gas compressor with a new compressor in same location

- Scope included process, piping, structural, electrical and instrumentation design activities

- Design considered pipe spooling to the maximum extent and shutdown planning for MCC modifications

- Orbital led constructability reviews to identify lifting locations and equipment staging areas for the quick turnaround window

Deliverables

- Revised P&IDs and general arrangements

- Piping plans, sections & elevations, isometrics

- Structural pipe supports drawings, compressor skid anchorage and grouting details

- Single line diagrams, cable & conduit schedules and grounding plan

- Schematic wiring diagrams, instrument list and instrument installation details

- Scope of work documents for construction

Project Highlights

- Successfully completed compressor replacement with minimal downtime. The existing compressor was demolished, and new compressor was installed and commissioned in same location in just 4 days.

- Total Installed Cost (TIC) – $2MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

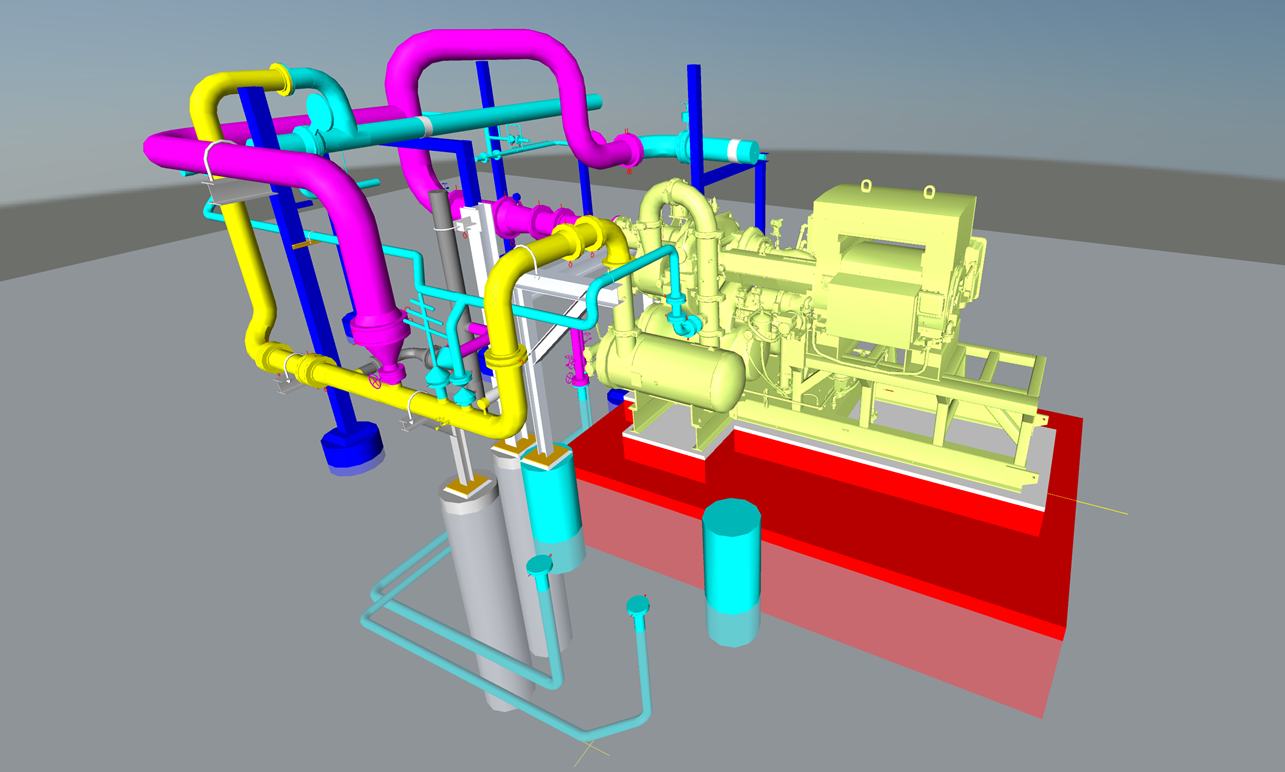

SRU Revamp

Oil and Gas

SRU Revamp

Oil and Gas

Scope of Work

- Developed FEED package with +/- 10% total installed cost estimate for a sulfur recovery unit revamp

- Project aimed to address constrained capacity, frequent faults and compliance gaps

- Orbital executed detailed design, start up and commissioning support for the project

Deliverables

- Process design basis, PFDs and P&IDs

- Material requisition packages for the new heater, boiler and tail gas treatment unit

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Foundation and steel drawings for supporting the new equipment, piping and conduit

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for demolition and installation

Project Highlights

- 80% of the linear feet of installed piping was jacketed. Laser scanning accuracy and plant 3D modeling was critical to preventing field installation issues of the jacketed piping in the field.

- Total Installed Cost (TIC) – $12MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Gum Treatment Project

Specialty Chemical

Gum Treatment Project

Specialty Chemical

Scope of Work

- This project included the installation of a new 40 ft tall retention tanks, 4 plate and frame exchangers, 25 ft tall feed tanks and centrifuge within multi-level process structure, cooling tower, inline mechanical shear mixer, clean-in-place (CIP) system (pump, tank, and controls), air purge system, multiple pumps (centrifugal and PD), and piping

- Orbital developed the FEED package and executed detailed design and construction management for the project

Deliverables

- Process design basis, PFDs and P&IDs

- Material requisition packages for all process equipment

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Foundation and steel drawings for supporting new equipment, piping and cable tray

- Single line diagrams, power plans, cable tray plans, lighting plans, grounding plans, cable and conduit schedules

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for construction

Project Highlights

- Spooling and prefabricated steel allowed above grade construction to be completed during a fast-track turnaround of 14 days.

- Total Installed Cost (TIC) – $6MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Featured

Natural Gas Processing

Natural Gas

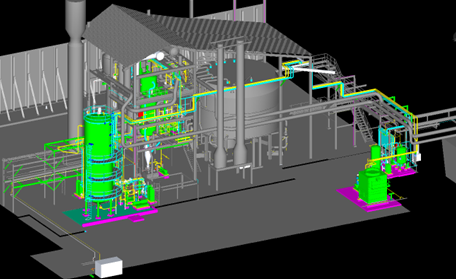

Natural Gas Processing

Natural Gas

Scope of Work

- Demolition of existing natural gas storage well metering and withdrawal dehydration systems at two adjacent sites, reconfiguration of existing system at one of the sites and tie-in of all wells to new dehydration, metering and pressure regulation

- In addition to multi-discipline engineering for all disciplines, Orbital supported procurement activities through bid reviews, technical bid evaluations and vendor document reviews

Deliverables

- Process Design Basis, PFDs and P&IDs,

- Revised Site Plan incorporating changes for storm water runoff and drainage, fencing and landscaping

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Foundation and steel drawings for supporting the new equipment and buildings

- Single line diagrams, power plans, duct bank and cable tray plans, lighting plans, grounding plans, cable & conduit schedules, lightning protection design, panelboard schedules

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for demolition and installation

Projects Highlights

- Orbital adapted to client request to change dehydration technology early in the project and dehydration location mid-project due to permitting constraints with minimum impacts to overall schedule. All dehydration, metering, pressure regulation and waste stream storage and transfer was housed in a single Operations building.

- Total Installed Cost (TIC) – $10MM

More Projects

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Featured

345k Double Breaker Interconnect Substation

Construction Management

Featured

Federal Funded Maintenance Program Management

Natural Gas

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Featured

Blast Furnace Gas Main Replacement

Steel

Blast Furnace Gas Main Replacement

Steel

Scope of Work

- Design blast furnace gas main replacement

- Supported project from early stages of existing facility documentation research, infrastructure inspection and utility investigation through flow modeling, detailed design and construction management

- Led shutdown planning following review of existing isolation (valves, blinds) and design incorporation of new isolation where required

Deliverables

- Flow model for confirmation of gas main sizing

- Goggle valve replacement packages including design drawings, sections, details and scope of work

- Inspection reports, standard repair details and engineering repair and replacement drawings, where required

Project Highlights

- Project showcased the uniqueness of Orbital with full-service asset integrity investigation and engineering solutions from one firm.

- Total Installed Cost (TIC) – $25MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Featured

345k Double Breaker Interconnect Substation

Construction Management

Featured

Federal Funded Maintenance Program Management

Natural Gas

Asset Management

Turnkey Fireproofing and Structural Repairs of Mechanical Equipment

Specialty Chemical

Turnkey Fireproofing and Structural Repairs of Mechanical Equipment

Specialty Chemical

Scope of Work:

- Executed a turnkey repair project for seven process vessels, providing services from inspection through repair and reinstatement

- Removed deteriorated intumescent and cementitious fireproofing from vessel column skirts and anchor bolt assemblies

- Performed abrasive blast cleaning to prepare vessel skirts for inspection and recoating

- Conducted detailed inspections, including visual assessments and ultrasonic thickness (UT) testing

- Evaluated corrosion damage using calipers and pit gauges

- Performed engineering evaluations to determine fitness for continued service

- Designed and implemented structural repairs to restore vessel integrity

- Completed final coating and reapplication of fireproofing

Deliverables:

- Inspection reports documenting visual findings and UT measurements

- Engineering evaluation and structural analysis

- Issued-For-Construction (IFC) drawings for anchor bolt replacement and base ring stiffener installation

- Completed structural repairs, including anchor bolt and stiffener installation

- Restored fireproofing and protective coating systems

Project Highlights:

- Orbital delivered a fully integrated turnkey repair solution for seven process vessels, seamlessly coordinating inspection, engineering, and field execution to minimize downtime and client oversight. Early identification of critical anchor bolt corrosion allowed Orbital to implement targeted structural repairs before further degradation could impact safety or operations. The project restored structural capacity and fire protection systems, extending the service life for each asset and improving long-term reliability. This effort highlights Orbital’s ability to deliver efficient, cost-effective repair solutions for critical infrastructure through a single, accountable team.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Railroad Loading Stations

Specialty Chemical

Railroad Loading Stations

Specialty Chemical

Scope of Work

- Project added six new sulfuric acid railcar loading stations to the existing chemical facility

- The additional stations and gangways were added along with new piping, pumps and instrumentation for facility operations

Deliverables

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Steel drawings for extension of the existing loading area and moveable gangways to accommodate railcars of different sizes

- Single line diagrams, power plans, conduit plans, lighting plans, grounding plans, cable and conduit schedules

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for installation

Project Highlights

- Railcar logistics drastically reduced costs over existing tanker transport means.

- Total Installed Cost (TIC) – $8MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Heavy Industrial

Chemical Plant

Specialty Chemical

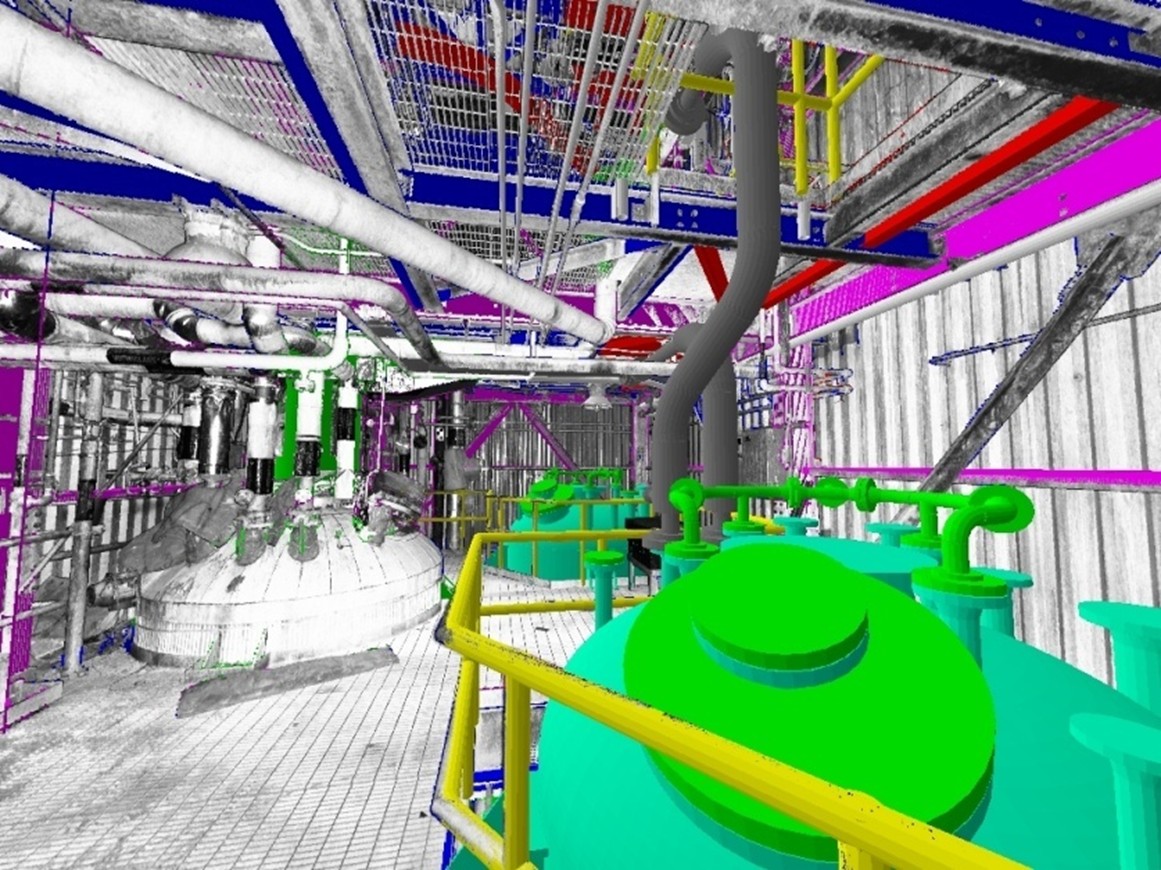

Chemical Plant

Specialty Chemical

Scope of Work

- Project included the installation of two new reactors into an existing enclosed facility

- Laser scanning was conducted to collect field data for the 10-level existing facility

- One new reactor was tied into the existing DCS system with the other reactor expected to be tied in at a later date

Deliverables

- Navisworks model, general arrangement drawings, piping plans and isometrics

- Steel drawings for supporting the new reactors, piping and conduit

- Instrument location plans, wiring diagrams, loop diagrams, instrument datasheets

- Scope of work documents for construction

Project Highlights

- Laser scan data supported constructability reviews and definition of demolition needed to lower the 2 new reactors through the roof and down to level 3.

- Total Installed Cost (TIC) – $3.2MM

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

Asset Management Program for a Steel Mill Client

Steel

Asset Management Program for a Steel Mill Client

Steel

Scope of Work:

- Supported a major steel client in the development and ongoing evolution of their corporate asset management program

- Provided technical assistance in creating the original corporate inspection procedure and supporting subsequent revisions

- Applied decades of hands-on inspection experience across structural and mechanical assets at domestic and international facilities

- Defined and refined inspection and reporting processes used across the client’s enterprise

- Coordinated and supported field inspection operations to align with corporate standards and safety requirements

- Integrated emerging technologies and digital tools to enhance inspection efficiency and data management

Deliverables:

- Corporate inspection procedures and revisions

- Digital inspection data outputs supporting asset tracking and long-term program management

- Standardized inspection and reporting frameworks, including:

- Defined inspection levels

- Standard reporting formats

- Means and methods documents for individual assets

- Documentation protocols

- Boundary documents

Project Highlights:

- Orbital played a foundational role in building and evolving the client’s corporate asset management program, applying decades of inspection experience to create practical, safety-focused procedures adopted company-wide. Standardized inspection levels, reporting formats, and documentation protocols improved consistency and reliability across domestic and international operations. Through ongoing inspection programs and the integration of advanced technologies such as UAS inspections and digital data management, Orbital continues to drive continuous improvement. This long-term collaboration has helped modernize inspection practices while supporting OSHA/ANSI compliance and the client’s reliability-centered maintenance objectives.

More Projects

Featured

Natural Gas Processing

Natural Gas

Heavy Industrial

Feed Impurity Removal

Specialty Chemical

Heavy Industrial

Reactor Heating Process Improvement

Specialty Chemical

Asset Management

OH-Crane, Crane Runway and Building Inspection

Steel

Asset Management

Bridge Inspection and Turnkey Repairs

Power Generation

Asset Management

API 653 Tank Inspection and Floor Replacement

Specialty Chemical